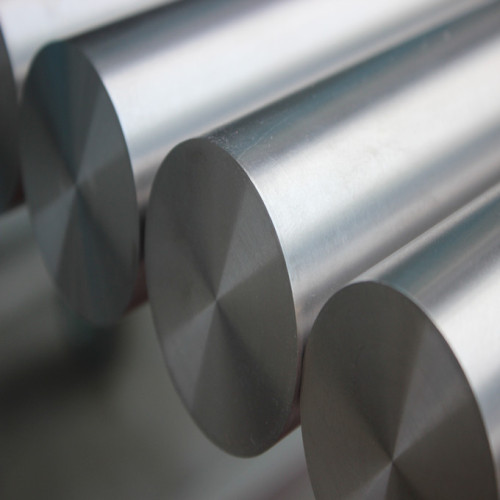

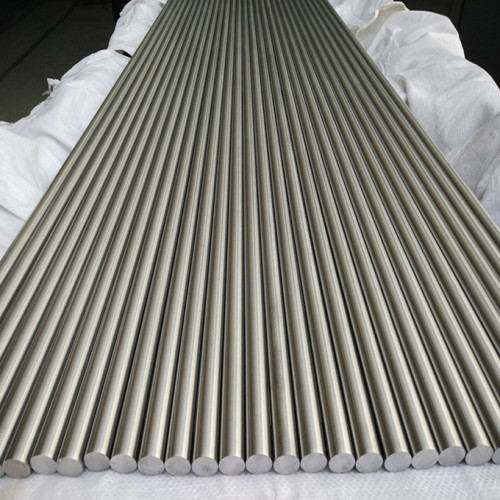

Gr5 6al 4v titanium alloy bar bar by forging processing with high strength used for defense

Item specifics

- Grade

- Gr5, Gr7, Gr9,Gr12, Gr23

- Diameter

- 6mm - 350 mm

- Length

- ≤6000mm

- Technology

- Hot-Rolled, Hot forging , Machining

- Condition

- Cold rolled(Y), Hot rolled(R), Annealed (M)

- Surface

- Pickling surface, Polished surface, Black surface

- Specifications

- Aerospace, Medical, Industrial

Review

Description

As a titanium bar manufacture,we know how to make titanium bars , our stock materials have been strictly inspected and the quality is guaranteed. We provide titanium bar cost low in stock. The following are detailed information about our materials.

|

Grade |

Gr5, Gr7, Gr9, Gr12, Gr23 |

||

Standard | ASTMB348,ASTM F136,AMS4928 | ||

|

Length |

≤6000mm |

||

|

Technology |

Hot-Rolled, Hot forging , Machining |

||

|

Condition |

Cold rolled(Y), Hot rolled(R), Annealed (M), Quenching(C)

|

||

|

Surface |

Pickling surface, Polished surface, Black surface |

||

|

Specifications |

Aerospace, Medical, Industrial

|

||

Chemical composition

Chemical composition, weight percent (%) | |||||||||||||||

Grade |

C ≤ |

O ≤ | N ≤ |

H ≤ |

Fe ≤ | Al | V |

Pd |

Ru | Ni | Mo | Other Elements Max. each | Other Elements Max. total | ||

Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 | |||

Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 | ||

Gr9 |

0.08 |

0.35 | 0.02 |

0.015 |

0.25 | 2.5~3.5 | 2.0~3.0 |

— |

— | — | — | 0.1 | 0.4 | ||

Gr12 |

0.08 |

0.25 | 0.03 |

0.015 |

0.30 | — | — |

— |

— | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 | ||

Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5-6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 | ||

Physical properties

Grade | Physical properties | ||||||

|

Tensile strength Min |

Yield strength (0.2%, offset) |

Elongation in 50mm Min (%) |

|||||

ksi | MPa | Min | Max | ||||

ksi | MPa | ksi | MPa | ||||

Gr5 | 130 | 895 | 120 | 828 | — | — | 10 |

Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

|

Gr9 |

90 |

620 | 70 |

483 |

— | — | 15 |

|

Gr12 |

70 |

483 | 50 |

348 |

— | — | 18 |

Gr23 | 120 | 828 | 110 | 759 | — | — | 10 |

Tolerance (mm)

Diameter | tolerance | ||

Hot forging bar | Hot rolling bar | Cold rolling bar | |

6~15 | ±1.0 | ±0.60 | ±0.30 |

16~25 | ±1.5 | ±0.70 | ±0.40 |

26~40 | ±2.0 | ±1.0 | ±0.50 |

|

41~60

|

±2.5

|

±1.5

|

±0.60

|

|

61~90

|

±3.0

|

±2.0

|

±0.80

|

|

91~120

|

±3.5

|

±2.2

|

±1.20

|

121~160 | ±5.0 | — | ±1.80 |

|

160~200

|

±6.5

|

—

|

±2.00

|

201~230 | ±7.0 | — | ±2.50 |

Features :

High tensile strength;

High corrosion resistance;

Low density, good thermal stability;

Non-ferromagnetic;

Good bio-compatibility;

High temperature and low temperature resistance;

High resistance to strong acid and strong alkali and so on.

Application :

Medical implants, medical instruments;

Aerospace, Industry, Navigation, artifical bones;

Sporting products;

Electroplating equipment;

Machining field, Automobile field;

Axis machining, the frame of the planes;

The equipment used in the sea water;

Testing :

Chemical composition test,

Physical properties test,

Appearance defects inspection,

Ultrasonic flaw detection,

Eddy current testing.

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us