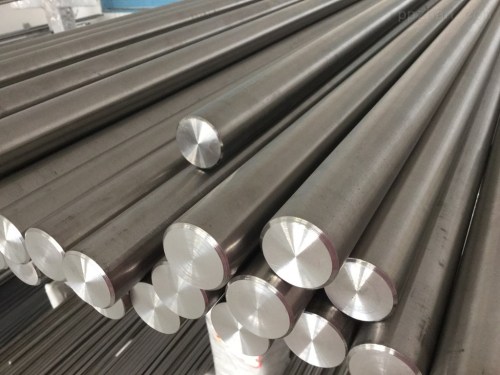

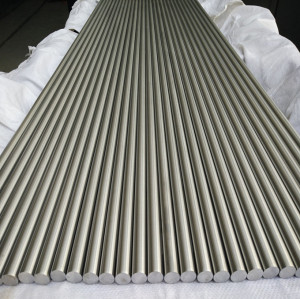

Pure grade 2 titanium bar with polished surface in stock for sale used in anti-corrosion

Item specifics

- Grade

- Gr1, Gr2, Gr3, Gr4,

- Diameter

- 0.5mm - 50 mm

- Length

- ≤6000mm

- Technology

- Hot-Rolled, Cold-Rolled, Hot forging , Machining

- Condition

- Cold rolled(Y), Hot rolled(R), Annealed (M)

- Surface

- Pickling surface, Polished surface, Black surface

- Specifications

- Aerospace, Medical, Industrial

Review

Description

AS a titanium rod manufacture,We can produce gr2 titanium bar , titanium industrial bar and titanium meidcal bar.All our materials we have been strictly inspected and the quality is guaranteed. You can buy titanium bar from our stock with cutting services. The following are detailed information about our titanium sheets.

|

Grade |

Gr1, Gr2, Gr3, Gr4, |

||

Standard | ASTMB348,ASTM F67 | ||

|

Diameter |

5mm - 250 mm |

||

|

Length |

≤6000mm |

||

|

Technology |

Hot-Rolled, Cold-Rolled, Hot forging , Machining |

||

|

Condition |

Cold rolled(Y), Hot rolled(R), Annealed (M), Quenching(C)

|

||

|

Surface |

Pickling surface, Polished surface, Black surface |

||

|

Specifications |

Aerospace, Medical, Industrial

|

||

Chemical composition

Grade | Chemical composition, weight percent (%) | ||||||||||||||

|

C ≤ |

O ≤ | N ≤ |

H ≤ |

Fe ≤ | Al | V |

Pd |

Ru | Ni | Mo | Other Elements Max. each | Other Elements Max. total | |||

Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 | ||

Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 | ||

|

Gr3 |

0.08 |

0.35 | 0.05 |

0.0015 |

0.30 | — | — |

— |

— | — | — | 0.1 | 0.4 | ||

|

Gr4 |

0.08 |

0.25 | 0.03 |

0.015 |

0.30 | — | — |

— |

— | — | — | 0.1 | 0.4 | ||

Physical properties

Grade | Physical properties | ||||||

|

Tensile strength Min |

Yield strength (0.2%, offset) |

Elongation in 50mm Min (%) |

|||||

ksi | MPa | Min | Max | ||||

ksi | MPa | ksi | MPa | ||||

Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

|

Gr3 |

65 |

450 | 55 |

380 |

80 | 550 | 18 |

|

Gr4 |

80 |

550 | 70 |

483 |

95 | 655 | 15 |

Tolerance (mm)

Thickness | Width tolerance | ||

400~1000 | 1000~2000 | >2000 | |

5.0~6.0 | ±0.35 | ±0.40 | ±0.60 |

6.0~8.0 | ±0.40 | ±0.60 | ±0.80 |

8.0~10.0 ±0.50 | ±0.50 | ±0.60 | ±0.80 |

|

10.0~15.0

|

±0.70

|

±0.80

|

±1.00

|

|

15.0~20.0

|

±0.70

|

±0.90

|

±1.20

|

|

20.0~30.0

|

±0.90

|

±1.00

|

±1.20

|

30.0~40.0 | ±1.10 | ±1.20 | ±1.50 |

|

40.0~50.0

|

±1.20

|

±1.50

|

±2.00

|

50.0~60.0 | ±1.60 | ±2.00 | ±2.50 |

Testing :

Chemical composition test,

Physical properties test,

Appearance defects inspection,

Ultrasonic flaw detection,

Eddy current testing.

Medical implants, medical instruments;

Aerospace, Industry, Navigation, artifical bones;

Textile printing and dyeing;

Sporting products;

Electroplating equipment;

Machining field, Automobile field;

Axis machining, the frame of the planes;

The equipment used in the sea wate

Features :

High tensile strength;

High corrosion resistance;

Low density, good thermal stability;

Non-ferromagnetic;

Good bio-compatibility;

High temperature and low temperature resistance;

High resistance to strong acid and strong alkali and so on.

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us