Which is better, titanium alloy or stainless steel?

- Share

- Issue Time

- Oct 26,2021

Summary

Which is better, titanium alloy or stainless steel?( how to weld titanium exhaust pipe?)The difference between titanium and titanium alloy and stainless steel.

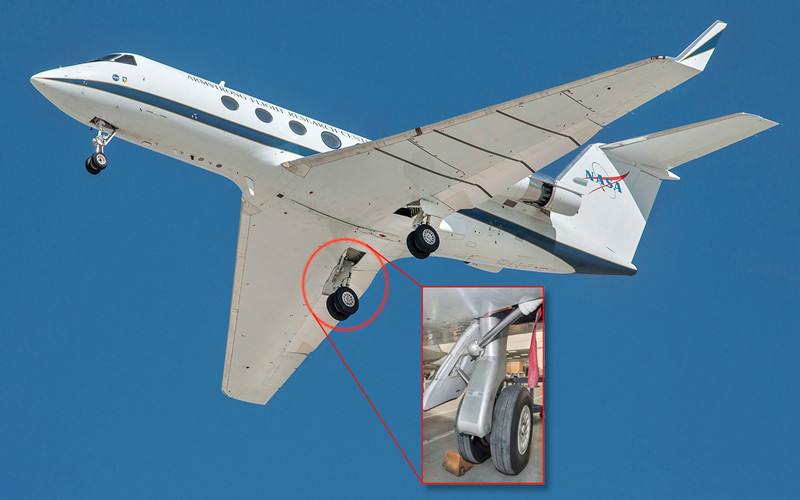

The difference between titanium and titanium alloy and stainless steel.Titanium cnc parts are used to make airplanes.and have custom titanium parts,titanium sprocket nuts,AMS 4901 titanium sheet,AMS 4911 titanium sheet etc.

The density of titanium and titanium alloys is only 4.51, which is smaller than steel and only half the weight of steel, but its strength is similar to that of ordinary carbon steel. Titanium is a thermodynamically unstable metal and is very active. Titanium metal can form a natural oxide film (titanium dioxide) with the air. This stable, strong adhesion, and excellent protective oxide film determines the corrosion resistance of titanium. Therefore, titanium has excellent corrosion resistance, followed by light texture, high tensile strength, and good mechanical properties are other outstanding characteristics of titanium alloys.

Titanium alloys can be divided into corrosion-resistant titanium alloys, structural titanium alloys, heat-resistant titanium alloys, and low-temperature titanium alloys.

1. It can be distinguished from the color. Titanium is a bit dark, revealing a cool color, which feels cool. Titanium is a bit darker than steel. The steel is white, pale. The two colors are very contrasting and can be seen.

2. It can also be distinguished by chemical methods, that is, soak it with nitric acid. Titanium does not react, and a strong reaction occurs when stainless steel is put down. The distinction between pure titanium and titanium alloys is difficult to see from the outside.

3. Titanium can make gray-black marks on ceramic tiles, but stainless steel can't make marks.

4. Titanium has good corrosion resistance: it is easy to form a dense oxide film under 550℃, so it is not easy to be further oxidized, and it has high resistance to large gas, sea water, steam, and some acids, alkalis, and soft media. Corrosion resistance.

5. Titanium has good thermal strength: Titanium alloy has a melting point of 1660°C, which is higher than iron, and has a higher thermal strength. It can be below 550°C and exhibits better toughness at low temperatures.

6. Titanium processing is difficult: welding, electroplating, and cold drawing are very difficult. Welding and electroplating must be carried out in vacuum or under inert gas conditions (vacuum ion plating)

Titanium alloys are widely used in various fields because of their high strength, good corrosion resistance, and high heat resistance.

The density of titanium alloy is generally about 4.51g/cm3, which is only 60% of steel. The density of pure titanium is close to that of ordinary steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials.Parts with high unit strength, good rigidity and light weight can be produced. The aircraft's engine components, skeletons, skins, fasteners and landing gear all use titanium alloys.

304 is a versatile stainless steel, which is widely used to make equipment and parts that require good overall performance (corrosion resistance and formability). In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 18% chromium and more than 8% nickel.

The density is 7.93 g/cm3, which is also called 18/8 stainless steel in the industry. High temperature resistance of 800 degrees, with good processing performance and high toughness, it is widely used in industry and furniture decoration industry and food and medical industry.

Of course, titanium alloy is better than 304, high strength, low density, corrosion resistance.