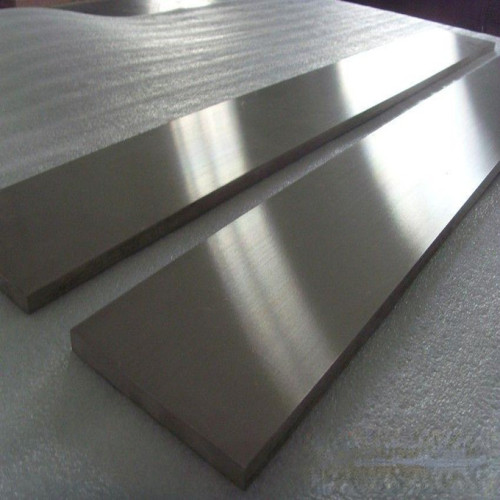

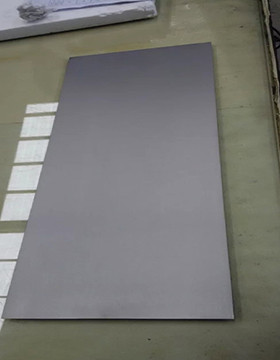

Good pressure resistance tantalum sheet used in aerospace and electronic energy industry

Item specifics

- Grade

- R05200, R05400

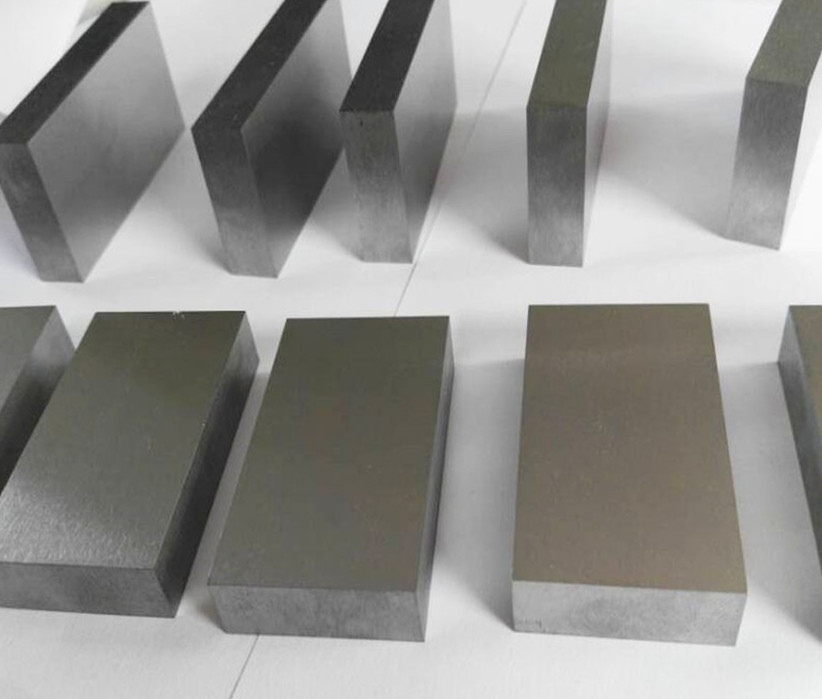

- Thickness

- 0.5mm - 20mm

- Width

- 20~1000mm

- Length

- 20mm~2000mm

- Technology

- Cold-Rolled,Hot rolled(R), Annealed (M)

- Condition

- Hard, Semi-hard, Mild

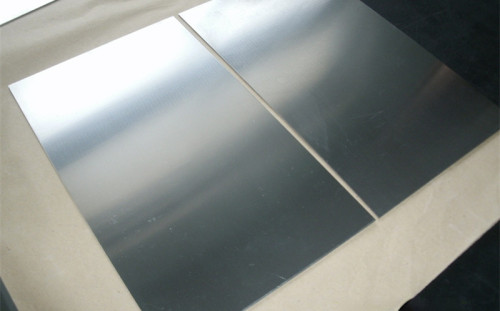

- Surface

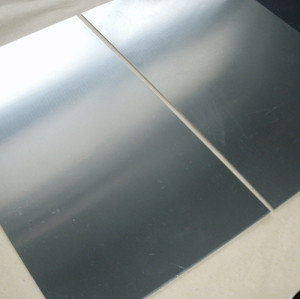

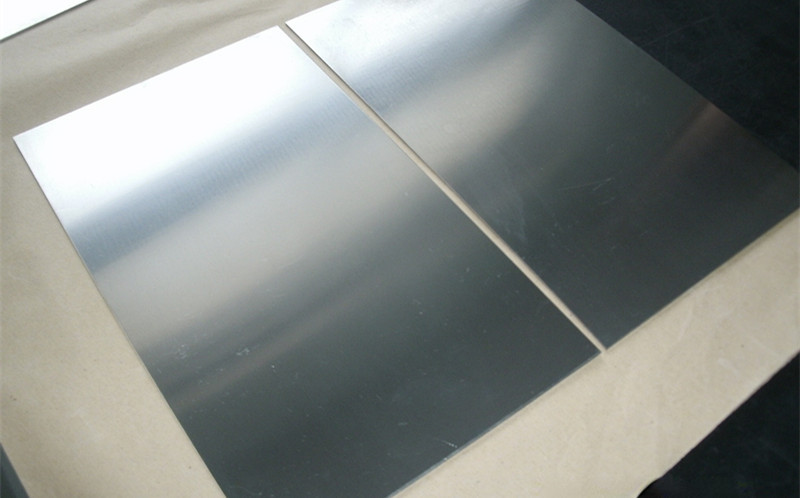

- polished surface,black surface

- Specifications

- Industrial,Aerospace,Medical

Review

Description

All of our tatanlum plate we have been strictly inspected and the quality is guaranteed. as a tantalum sheets supplier we provide polished tantalum alloy sheet treatment and cutting tantalum sheet services with good price. The following are detail informations about our tantalum sheet stock materials.

|

Grade |

R05200, R05400 |

||

Standard | ASTMB708 | ||

|

Thickness |

0.5mm - 20 mm |

||

|

Width |

20mm - 1000mm |

||

|

Length |

≤2000mm |

||

|

Technology |

Hot-Rolled, Cold-Rolled, Hot forging , Machining |

||

|

Condition |

Hard, Semi-hard, Mild

|

||

|

Surface |

Polished surface, Black surface |

||

|

Specifications |

Aerospace, Medical, Industrial

|

||

Chemical composition

|

Element

|

C | O | N | H | F | Mo | Nb | Ni |

Si

|

Ti

|

W

|

|

RO5200(% Max)

|

0.01 | 0.015 | 0.01 | 0.0015 | 0.01 | 0.02 | 0.1 | 0.01 |

0.005

|

0.001

|

0.05

|

|

RO5400(% Max)

|

0.01 | 0.03 | 0.01 | 0.0015 | 0.01 | 0.02 | 0.1 | 0.01 |

0.005

|

0.001

|

0.05

|

Physical properties

|

Grade

|

Thickness |

Tensile strength Min (MPa) |

Yield strength Min (MPa) (2%Residual strain) |

Elongation Min (%) (25.4mm Gage) |

|

RO5200,RO5400

|

<0.1 |

207

|

138

|

20

|

≥0.1 |

172

|

138

|

30

|

Tolerance (mm)

Thickness | size tolerance | ||

0.5-20 | 20-1000 | 20-2000 | |

|

0..5~0.8

|

±0.04

|

±2.0

|

±2.0

|

|

0..8~1.0

|

±0.06

|

±2.0

|

±2.0

|

|

1.0~1.5

|

±0.08

|

±1.0

|

±1.0

|

1.5~2.0 | ±0.10 | ±1.0 | ±1.0 |

|

2.0~5.0

|

±0.15

|

±1.0

|

±1.0

|

5.0~8.0 | ±0.18 | ±1.0 | ±1.0 |

8.0~12 | ±0.20 | ±1.0 | ±1.0 |

12.0~15 | ±0.50 | ±1.0 | ±1.0 |

15.0~20 | ±0.80 | ±1.0 | ±1.0 |

Testing :

Chemical composition test,

Physical properties test,

Appearance defects inspection,

Ultrasonic flaw detection.

Application :

TElectron-beam melting,

Laboratory equipment,

Substitute for platinum,

Manufacturing super alloys,

Glass and ceramic industries,

Metallurgical,

Machinery processing,

Sputtering targets,

Aviation, aerospace industry,

Medical equipment, etc.

Features :

High melting point, low vapor pressure,

Good cold working performance,

High chemical stability, strong resistance to liquid metal corrosion,

Large dielectric constant of the surface oxide film.

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us