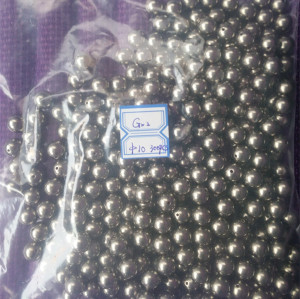

Grade2 machined titanium parts titanium ball friendly to boby health for titanium ball bracelet making

Item specifics

- Grade

- Gr1, Gr2, Gr3, Gr4,Gr5,Gr7,Gr9,Gr12

- Diameter

- according to drawing

- Standard

- according to customer request

- Technology

- Hot forging, cold rolling, Machining

- Surface

- mechined surface, bright surface,Black surface

- Specifications

- Aerospace, Environmental protection , Industrial

Review

Description

We are titanium cnc parts manufacture . and we always produce mechined titanium parts,titanium alloy parts,titanium aerospace parts accroding to customer requirement .The following are the informations about our titanium parts grade .

|

Grade |

Gr1, Gr2, Gr3, Gr4, Gr5,Gr7,Gr9,Gr12,Gr23 |

||

Standard | according to customer requirement | ||

|

Diameter |

according to drawing |

||

|

Technology |

Hot-forging, Machining |

||

|

Surface |

bright surface, machined surface, Black surface,pickling surface |

||

|

Specifications |

Aerospace, Medical, Industrial

|

||

Chemical composition

Grade | Chemical composition, weight percent (%) | ||||||||||||||

|

C ≤ |

O ≤ | N ≤ |

H ≤ |

Fe ≤ | Al | V |

Pd |

Ru | Ni | Mo | Other Elements Max. each | Other Elements Max. total | |||

Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 | ||

Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 | ||

|

Gr3 |

0.08 |

0.35 | 0.05 |

0.0015 |

0.30 | — | — |

— |

— | — | — | 0.1 | 0.4 | ||

|

Gr4 |

0.08 |

0.25 | 0.03 |

0.015 |

0.30 | — | — |

— |

— | — | — | 0.1 | 0.4 | ||

Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 | ||

Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 | ||

Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 | ||

Gr12 | 0.08 | 0.30 | 0.03 | 0.015 | 0.30 | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 | |||||

Gr23 | 0.08 | 0.13 | 0.03 | 0.0125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 | ||

Physical properties

Grade | Physical properties | ||||||

|

Tensile strength Min |

Yield strength (0.2%, offset) |

Elongation in 50mm Min (%) |

|||||

ksi | MPa | Min | Max | ||||

ksi | MPa | ksi | MPa | ||||

Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

|

Gr3 |

65 |

450 | 55 |

380 |

80 | 550 | 18 |

|

Gr4 |

80 |

550 | 70 |

483 |

95 | 655 | 15 |

Gr5 | 130 | 895 | 120 | 828 | — | — | 10 |

Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

Gr9 | 90 | 620 | 70 | 483 | — | — | 15 |

Gr12 | 70 | 483 | 50 | 340 | — | — | 18 |

Gr23 | 120 | 828 | 110 | 759 | — | — | 10 |

Testing :

Chemical composition test,

Physical properties test,

Appearance defects inspection,

Dimensional tolerance check。

Bicycle, motorcycle, automobile,

Racing car, yacht, sports, electronics,

Pharmaceutical, petroleum, metallurgy,

Chemical, seawater desalination,

Ocean engineering,

Construction and other industries.

Features :

High tensile strength;

High corrosion resistance;

Low density, good thermal stability;

Non-ferromagnetic;

Good bio-compatibility;

High temperature and low temperature resistance;

High resistance to strong acid and strong alkali and so on.

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us