Why is "Ocean Metal" titanium alloy so suitable for submarines? What are its advantages?titanium sheet stock thickness.

- Share

- Issue Time

- Dec 28,2021

Summary

The superiority of marine metal-titanium used on submarines.titanium sheet stock thickness.

Titanium and titanium alloys are new materials developed in the 1950s. With the development of naval equipment, the requirements for naval equipment are getting higher and higher, and traditional steel, iron, aluminum, magnesium and other metals and their alloys can no longer meet the requirements in many fields. Titanium alloys are receiving increasing attention from ships and marine engineering equipment due to their excellent properties, and are called "marine metals". As the core of "naval equipment", submarines are the backbone of strategic nuclear forces and play a pivotal role. Can the use of titanium alloys to make submarines bring new breakthroughs in performance to submarines? Today I will briefly analyze the superiority of titanium alloys used in submarines.

The first advantage-high specific strength

"Specific strength" refers to the ratio of material strength to density. The greater the specific strength, the smaller the structural weight can be obtained with the same strength design, and the higher the strength can be obtained with the same structural quality. The high specific strength can make the equipment design more compact, greatly reduce the structural quality, and improve the safety of the equipment.

The effect of high specific strength on the pressure shell

When the submarine structure is timed, the submarine’s ultimate diving depth is proportional to the product of the yield strength of the shell material and the shell thickness. Increasing the depth of the dive by thickening the pressure shell will reduce the effective load of the submarine. If the effective load is maintained, the size of the submarine will be increased to the extent that it is practically unusable, thereby reducing the overall performance of the submarine. Therefore, the use of higher specific strength materials must be considered.

Performance data of several deep submarine pressure hull materials

From the performance data of several deep submarine pressure hull materials in the above table, it can be seen that although the yield strength of titanium alloy is not as good as that of high-strength steel, it has a lower density and higher specific strength. It is currently available for submarine hulls. The performance of the material is the best, so titanium alloy is very advantageous for use as a pressure-resistant shell material for submarines and deep submersibles. In reality, the submerged depths of two Russian titanium alloy submarines can reach 800-1000 meters; and the pressure hulls of most of the world's deep submersibles are made of titanium alloy.

Jiaolong submersible

The effect of high specific strength on the propeller

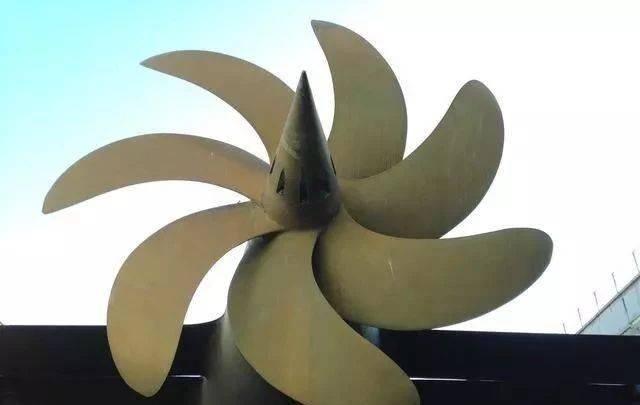

Modern submarines, in order to pursue quiet performance, mostly use large-diameter, low-speed, seven-blade, large-tilted propellers, which have a larger structure and heavier weight. The propeller shaft of the submarine itself is a cantilever beam. When the weight of the free end is large, the propeller shaft will bend and the stern bearing will be loaded. In addition, when the weight of the transmission shaft itself is large, it will aggravate the bending of the shaft system. The use of materials with higher specific strength to manufacture the drive shaft and propeller can reduce the uneven bearing load caused by the bearing turbulence and the shaft vibration problem caused by this.

The propeller of a submarine

The second advantage-excellent corrosion resistance

Titanium has higher corrosion resistance than other commonly used metal materials in neutral and oxidizing environments and many harsh environments, especially for chloride ions in seawater. It has strong corrosion resistance. A very thin and strong oxide film can be formed on the surface of titanium, which can passivate titanium without being corroded by seawater. The passivation film of titanium has good self-healing properties, and can be repaired quickly and automatically after being damaged or scratched to form a new protective film. It is this oxide film that protects titanium from seawater corrosion. Without chemical changes and pollution, titanium can completely resist the corrosion of natural seawater.

Corrosion of sea water to ships

Excellent corrosion resistance affects pipelines and valves

Sea water is very corrosive to the hull, but with the development of anti-corrosion technology, the hull of the ship adopts corrosion-resistant steel, anti-corrosion paint, electrochemical anti-corrosion and other means to ensure the safety of the hull during its lifetime. However, the piping system of the submarine is very complicated, and it is easy for the process to be inadequate, and the high flow velocity in the pipeline aggravates corrosion. According to related tests, tin bronze valves and 70/30 copper-nickel alloy pipes have been used for 15 months at a water velocity of 4.5m/s, and the valves and pipes are perforated; while the all-titanium pipe system is used at a water velocity of 6m/s 36 months without any visible changes. This means that the use of titanium and titanium alloy materials in submarine seawater piping and valves can reduce the pipe diameter and increase the water speed and extend the service life.

The complicated pipeline inside the submarine

The third advantage-good sound permeability

Sonar is the "eye" of the submarine, and to protect the sonar, the sonar will be placed in the shell. Titanium alloys have high specific strength, low thermal expansion coefficient, high electrical resistance, and good sound transmission performance, which make them used in submarine acoustic devices. For example, the sonar dome of the former Soviet Union 607A nuclear submarine flying missile uses titanium alloy; and the sonar domes of the "Minsk" and "Kiev" aircraft carriers purchased by my country are also made of titanium. Made of alloy. Judging from these actual usage conditions, the sound transmission performance of titanium alloy is better than that of glass fiber reinforced plastic and stainless steel, which can effectively guarantee the performance of sonar.

titanium plate heat exchanger manufacturers,titanium plate in arm side effects,titanium steel multi hit plates,titanium gold sheet

Minsk

Conclusion

In general, the extensive use of titanium and titanium alloys in submarines can greatly reduce the structural weight of the submarine, achieve high mobility, and ensure the high reliability and safety of the submarine; the corrosion resistance can achieve the same service life and reduce the maintenance time of the submarine And cost, guarantee the combat effectiveness of equipment, and improve some other technical performance. Therefore, titanium alloy is an ideal material to ensure the equipment performance and tactical level of submarines, and has important strategic significance for the development of naval submarines.