Management of materials and environment before welding titanium composite plate tanks(titanium clad plate,titanium clad bar)

- Share

- Issue Time

- Nov 18,2021

Summary

Management of materials and environment before welding titanium composite plate tanks

It is reported that in order to ensure the processing quality of titanium composite plate cans, the materials and environment should be protected and cleaned before processing. The specific management practices are as follows:

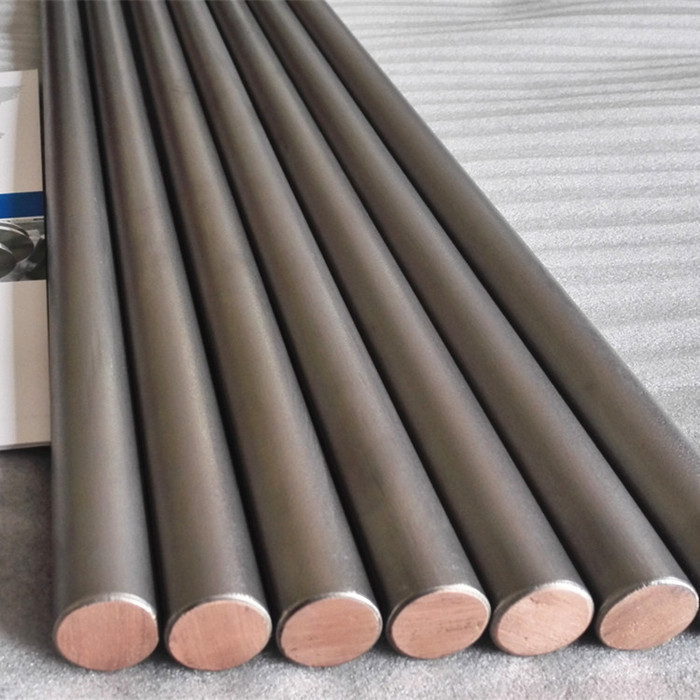

The following pictures show various titanium composite materials. Common titanium composite products are: titanium clad copper rod(titanium clad copper bar),titanium clad plate(titanium clad steel plate),titanium clad copper rod.Our company supplies the above several titanium composite products all year round.

One. Material:

1. Each material, including welding materials, should meet the requirements specified in the drawings and related technical standards.

2. Material management:

(1) The surface of the titanium sheet and the composite sheet should be protected by a paper film to avoid contamination by dust, oil, iron ions and other dirt, and to avoid scratching the surface of the titanium material during handling or processing.

(2) Titanium and titanium composite panels should be stored separately from other materials, and the storage environment should be kept clean. The bottom of the material should be supported with clean wood (to ensure that there are no hardware such as nails), and the upper part should be covered with plastic cloth.

(3) Every handling equipment and forming equipment, such as bending machines, presses and lifting fixtures, should be cleaned. Defects such as burrs and nicks that cause damage and contamination of the titanium surface on the equipment should be locally polished and polished. If necessary, in order to protect the titanium surface from damage and contamination, it should be properly covered during use of the equipment.

(4) When welding, the titanium surface must be protected with a clean, soft mat or felt to prevent the welding material from damaging the surface.

Two. Manufacturing environment:

1. The welding and assembly of the titanium composite plate tank should be carried out in a clean workshop. It is strictly forbidden to weld or assemble in areas with iron and dust to avoid contamination by iron ions or other dirt. Rubber or other soft materials should be laid on site to avoid impact and scratches on the titanium surface. Frequently clean up the site and clean up debris.

2. Tools in contact with titanium should be made of titanium or aluminum. Stainless steel tools are used sparingly, and process approval is required before they can be used.

3. Personnel working in this environment should wear clean overalls, soft-soled cloth shoes or rubber shoes, and keep them clean. Work clothes should be kept clean, and work clothes should be placed in the auxiliary room of the cleaning workshop.

4. In order to check whether the welding environment of the titanium composite plate tank meets the requirements, the environment should be subjected to a phenanthroline test before welding to avoid the presence of iron ions.