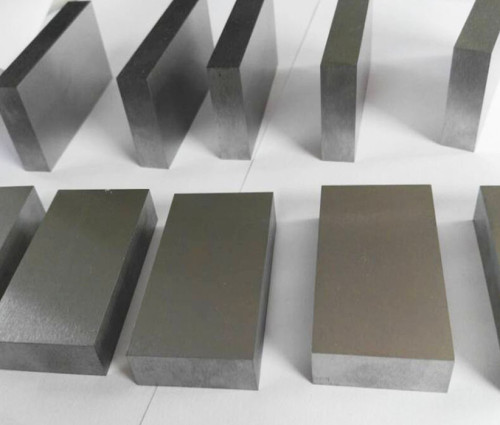

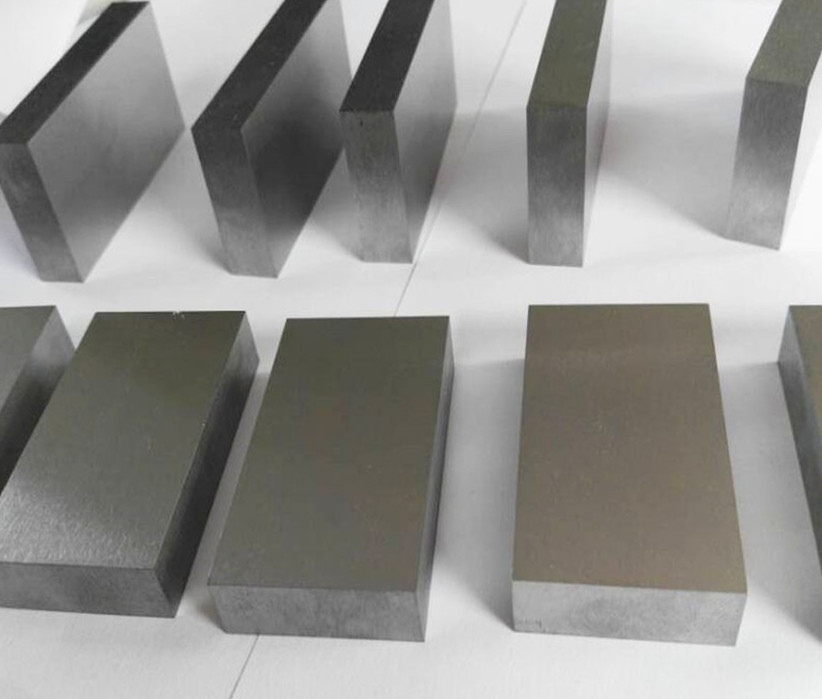

RO4200 niobium plate with astmb393 used for electronics&precision ceramics industry

Item specifics

- Grade

- R04200, R04210

- Thickness

- 0.5mm - 20mm

- Width

- 20~1000mm

- Length

- 20mm~2000mm

- Technology

- Cold-Rolled,Hot rolled(R), Annealed (M)

- Condition

- Hard, Semi-hard, Mild

- Surface

- polished surface,black surface

- Specifications

- Industrial,Aerospace,Medical

Review

Description

All of our niobium sheet have been strictly inspected and the quality is guaranteed. We are a professional niobium supplier who provide polished treatment and cutting niobium sheet services.and our niobium sheet price is good.The following are detail informations about our niobium materials.

|

Grade |

R04200, R04210 |

||

Standard | ASTMB393 | ||

|

Thickness |

0.5mm - 20 mm |

||

|

Width |

20mm - 1000mm |

||

|

Length |

≤2000mm |

||

|

Technology |

Hot-Rolled, Cold-Rolled, Hot forging , Machining |

||

|

Condition |

Hard, Semi-hard, Mild

|

||

|

Surface |

Polished surface, Black surface |

||

|

Specifications |

Aerospace, Medical, Industrial

|

||

Chemical composition

|

Element

|

C | O | N | H | Nb | Mo | Ta | Ni |

Si

|

Ti

|

W

|

|

RO4200(% Max)

|

0.0035 | 0.0012 | 0.003 | 0.0012 | Bal | 0.005 | 0.05 | 0.002 |

0.004

|

0.002

|

0.005

|

|

RO4210(% Max)

|

0.0050 | 0.0015 | 0.008 | 0.0015 | Bal | 0.01 | 0.07 | 0.005 |

0.01

|

0.004

|

0.02

|

Physical properties

|

Grade

|

Thickness |

Tensile strength Min (MPa) |

Yield strength Min (MPa) (2%Residual strain) |

Elongation Min (%) (25.4mm Gage) |

|

RO4200,RO4210

|

0.5-20 |

125

|

85

|

25

|

Tolerance (mm)

Thickness | size tolerance | ||

0.5-20 | 20-1000 | 20-2000 | |

|

0..5~0.8

|

±0.04

|

±2.0

|

±2.0

|

|

0..8~1.0

|

±0.06

|

±2.0

|

±2.0

|

|

1.0~1.5

|

±0.08

|

±1.0

|

±1.0

|

1.6~2.0 | ±0.10 | ±1.0 | ±1.0 |

|

2.0~5.0

|

±0.15

|

±1.0

|

±1.0

|

5.0~8.0 | ±0.18 | ±1.0 | ±1.0 |

8.0~12 | ±0.20 | ±1.0 | ±1.0 |

12.0~15 | ±0.50 | ±1.0 | ±1.0 |

15.0~20 | ±0.80 | ±1.0 | ±1.0 |

Testing :

Chemical composition test,

Physical properties test,

Appearance defects inspection,

Ultrasonic flaw detection.

Application :

Iron industry,

Superconducting Material Industry,

Aerospace Industry,

Atomic Energy Industry,

Electronics industry,

Medical field.

Features :

Rare metal with high boiling point,

Looks like steel, off-white luster,

Dark gray powder, with air absorption,

Corrosion resistance, superconductivity,

Unipolar conductivity and high strength at high temperature.

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us